Casting the net wider

Almost 20 years after its launch, the region’s premier science park, at Sedgefield, County Durham, is aiming for the stars.

Sectors represented at the site include advanced materials and manufacturing, nanotechnology, X-ray technology, semiconductors, defence, electronics, photonics, robotics, pharmaceutical – and, most recently, the space and satellite market.

NETPark, which is managed by Business Durham, the business support service for Durham County Council, has established high-level partnerships with the Centre for Process Innovation (CPI) and Durham University, and now hosts three national innovation centres – the National Formulations Centre, National Centre for Healthcare, and National Centre for Printable Electronics.

There are also two National Catapult Centres – the High Value Manufacturing Catapult, managed by CPI, and the North East Satellite Applications Centre of Excellence also managed by Business Durham. The “NET result” is that the science park is now home to more than 40 companies, employing more than 600 people, including the likes of aXenic, Dyman Advanced Materials, Filtronic, IBEX, Kromek, PragmatIic, and Wootzano. And work on Phase 3 is expected to start later this year, with Durham County Council investing £60m in an expansion that will provide up to a further 232,000sq. ft. for laboratories, offices, production facilities and storage.

The development is a crucial aspect in the council’s Inclusive Economic Strategy, which aims to shape the future of County Durham by creating more and better jobs in an inclusive, green economy.

An exciting new chapter in the NETPark success story is about to begin…

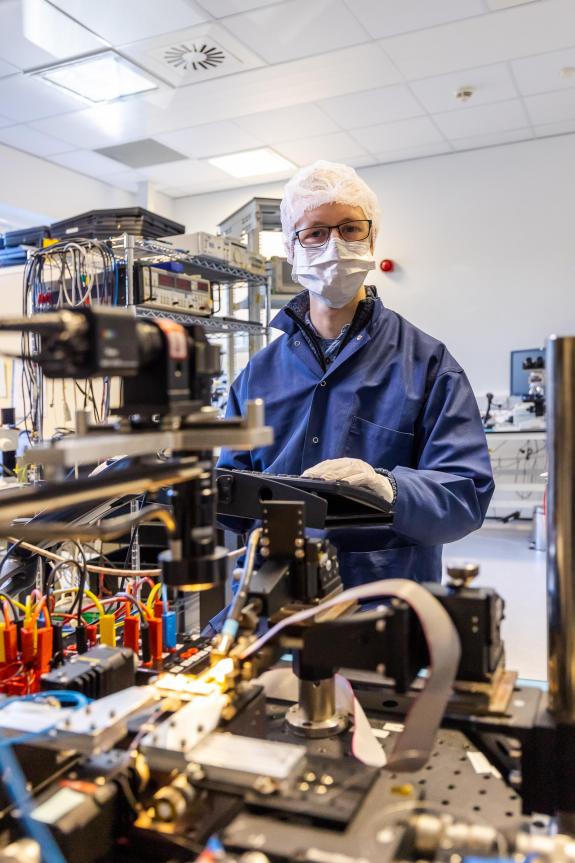

aXenic clean room at NETPark (Image: Business Durham)

Aiming higher than ever

As chief executive of a company that’s flourished at NETPark since 2009, Steve Clements has seen the site not only become established as the region’s premier science park, but gain national credibility.

“NETPark has clearly moved from being regionally important to a nationally important centre,” declares the CEO of aXenic.

aXenic is a leader in the design, development and production of ultra-high speed optical modulators, communications and sensing, particularly in the field of satellite communications. And Steve has no doubt that NETPark has played a critical part in the growth of the company as it prepares for an exciting future in the space sector.

Originally from Yorkshire, Steve has been immersed in the world of fibre optics since the 1980s when he helped enable the first fibre optic telecommunications links beneath the Pacific and Atlantic.

He came to the North-East in 2001 to work on the development of an optical business at Filtronic, then based at Newton Aycliffe. When the Filtronic plant was acquired by American company, RFMD, in 2009, the optics side of the business was sold on to German company u²t Photonics, based at NETPark.

By 2013, instead of expanding fibre optics on the ground, Steve could see an opportunity to approach customers who were active in satellite communications.

“We could see that the technology we were making was totally applicable for the internet and telecommunications from space, so it was a pivotal time,” recalls Steve.

When u²t was bought out by American company, Finisar, in 2014, it became clear that the new owners weren’t interested in the work Steve’s team were doing with fibre optics, so he cut a deal to form aXenic a year later.The initial business plan was to focus on Europe, working with leading satellite manufacturers, Airbus and Thales Alenia Space, but Covid came along just as aXenic was on the point of winning major contracts.

“Demand for what we were developing slowed down and we had to retrench,” says Steve.

But, instead of sitting on their hands, the aXenic team put the downtime of the pandemic to good use, bringing forward plans to expand worldwide. Agents were appointed around the world, the business began trading globally, and by the end of 2020, it was back in growth.

“From going through a sticky patch during Covid, things have really moved forward over the past two years,” says Steve.

From a start-up team of six when aXenic was founded, that’s doubled to 12 employees, and turnover has grown by more than 50 per cent in each of the last two years. In addition to the core team, the business uses the same number of sub-contractors, all based in the UK, and many of them in the North East.

aXenic was recently awarded a contract to supply its leading IQ modulator product for a large satellite-based communication application, which will deliver more than 200 parts through 2023, and Steve describes it as a “milestone moment” for the business.

“We are leading the world in what we do and, hopefully, this is the first of many contracts with that customer and other customers,” he says. “It’s what we’ve been anticipating for a long time, before Covid got in the way, and we are on the cusp of very significant growth.”

And NETPark will continue to be at the heart of that growth, with the company planning to be part of Phase 3, so it can expand its team, facilities and equipment.

“It’s an excellent place to do business and we want to be part of the expansion,” he adds.

“When you’re a small company, trying to attract the brightest and best talent, it’s a stronger sell when you’re part of a dynamic cluster of like-minded businesses.

“Durham County Council and Business Durham have been incredibly proactive in supporting the cluster and, when times are hard they can direct companies to sources of grants and income that make all the difference.

“There are other science parks around the country, but the level of support on NETPark is second to none, and I have no doubt that we will be enriched by a growing collection of world-class companies on the site.”

Gary Gibson, Founder and Chief Executive at Dyman Advanced Materials (Image: Business Durham)

A gem of a business

As a County Durham lad from a long line of miners, Gary Gibson has become a sparkling example of County Durham nurturing its own talent and looking to the future.

Gary grew up in Peterlee during the miners’ strike of the 1980s. His father, Ron, was a pitman at nearby Horden Colliery, as was his grandfather and great-grandfather.

“My dad could see there was no future in the pits, so he always stressed, again and again, that I should get an education that would give me a career that was anything but mining,” he recalls.

Gary followed his father’s sound advice but there was an irony in the educational route he chose because, when he went to Imperial College London to study for a degree and PhD in Material Science and Engineering, he was based at the Royal School of Mines.

After he graduated, he became a researcher at Cambridge University before moving into industry, working as a process engineer in semiconductor plants in this country and the US.

When he returned to the UK, he spent the next ten years as a technologist in various start-ups, including Durham companies, Kromek, a leading developer of radiation detection solutions, and X-ray specialist, Bede.

By 2012, Gary had gained enough experience to become founder of IBEX Innovations – a business making X-ray equipment for the early diagnoses of osteoporosis and other bone conditions – with NETPark as the chosen location.

As the business grew, a chief executive was brought in, and Gary got back to what he loves most – exploring the science.

His next venture, in 2018, was the launch of Dyman Advanced Materials, an exciting business developing a new and patented process for the production of high-quality synthetic diamonds for the industrial and jewellery sectors.

“It’s very difficult to tell the difference from real diamonds but they retail at 30-40 per cent less,” explains Gary. “There’s a very strong movement towards them, especially among young people in the US and Asia, because their production is not only cheaper but more environmentally friendly and ethical.”

When the business first started, it was just Gary and one other part-time employee, but that has now grown to ten members of staff, with seven full-time equivalents. For the past five years, the focus has been on research and development, but the business is now ready to start selling commercially.

The first samples will be ready for shipment in the next couple of months, with the initial focus on the industrial market.

“Our USP is that we’ve come up with a way of producing the lab-made diamonds that uses less power, making the process much more economical and environmentally friendly,” says Gary. “NETPark has been great during that R&D phase because you’re surrounded by like-minded companies, the facilities are amazing, and there’s a great support team on-site. They’ve been so helpful in opening up their contacts and giving advice.”

During development, Gary’s team needed access to sophisticated pieces of equipment and, by being part of a science business cluster, they were able to gain short-term access to equipment owned by other NETPark companies, either on a rental or goodwill basis.

He’s also grateful for the “very practical and sound business advice and support” the company has had from Business Durham. “It’s an organisation that wants to find solutions, and that’s not what you always find in other parts of the world,” he says. “They hold regular networking clinics, and fundraising services that are the lifeblood of a young company. It led to grant funding and angel investment for us.”

Durham Universitysponsored a PhD student to work on research and development projects that proved to be useful to the company, while CPI also helped find solutions to development problems. It means that the priority for this year is to build up the manufacturing side of the business by taking advantage of the Phase 3 expansion of NETPark.

“It is great that the council are committing to expand NETPark, and it was great that Business Durham reached out to companies on the park to ask what kind of facilities they would like to see in the expansion, so we’ve had a voice in what happens in the future. That’s the kind of inclusive place it is,” says Gary.

And, with confidence that the business is ready for commercialisation, the target is for Dyman to hit £20m in annual revenues over the next three years.

After five years spent patiently developing the production of synthetic diamonds in modern labs, that will be quite an achievement for the County Durham lad whose ancestors went underground to dig for coal.

To find out more about NETPark and the innovative business based on the park visit www.northeasttechnologypark.com