The extant employability needs of Industry 4.0: The criticality of technical education in 2022

By Dr. Gauri Bhasin,

Without a question, digitalization is a societal mega-trend. Nonetheless, the unpredictability of real changes brought on by digitization is frequently emphasized. The shift from analogue to digital information storage and processing was the catalyst for the developments. Digitalization, on the other hand, quickly became a symbol of societal change brought on by technical advancement.

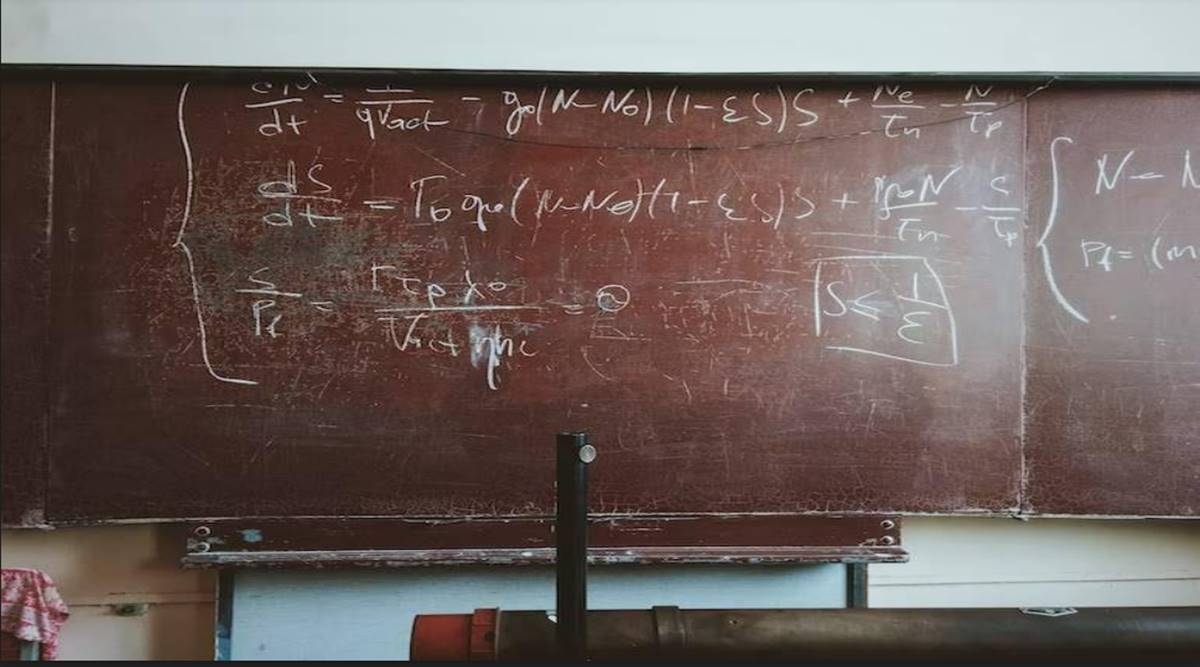

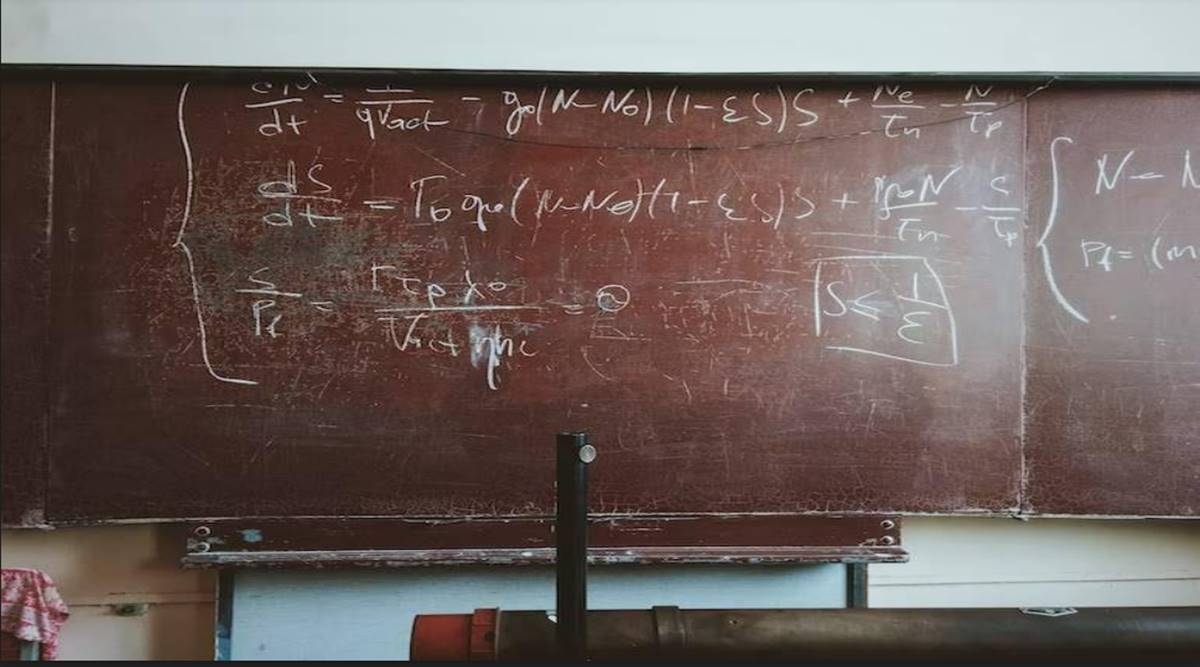

Industry 4.0 refers to “smart” and networked manufacturing systems that perceive, anticipate, and interact with the real world in order to make real-time production decisions. Talent and skills are treasured in knowledge-based economies. By merging the physical, digital, and biological worlds, the Fourth Industrial Revolution (4IR) has ushered in new paradigms in how people live, work, and interact. These innovations have prompted both excitement and worry—excitement at the prospect of expanding the frontiers of human achievement, and fear of negative consequences for jobs and rising inequality.

Using the Education 4.0 idea, educators and students have been able to improve higher education pedagogical procedures by leveraging modern infrastructure and rising technology. In this context, pedagogical methodologies are expanding and reorienting their paradigms toward innovation in training processes in order to satisfy the needs of a rapidly changing digital environment.

Also read| The shifts in business and tech education

Traditional teaching methods must be modified in Education 4.0 to integrate concepts, technologies, and activities that enable students to access relevant learning and training programmers. Since Education 4.0 aims to make academic interventions more efficient, accessible, and flexible, new teaching-learning methods emerge that take into account the use of technology as well as tried-and-true principles, strategies, styles, and pedagogical procedures that are increasingly used in higher education. New teaching-learning approaches are being given in many modalities as a result of these opportunities, allowing for greater knowledge development, information transfer, and resource utilization. As a result, new and innovative face-to-face, online, and blended learning programmes have emerged.

To put it another way, Industry 4.0 will necessitate the creation of a new type of worker—a knowledge worker! To adapt, manage, and take advantage of Industry 4.0, tomorrow’s industry leaders and managers will need new skill sets. They must be value-driven leaders, critical thinkers, problem solvers, innovators, communicators, and communicators. They must be able to see beyond the technology at hand to the societal ramifications of that technology’s application. The knowledge worker is defined by these characteristics. They must not only understand the technology, but also be able to face and solve all of the issues that come with it. A fresh approach to education is required for this type of leader.

Also read| Role of vocational education and training in reducing unemployment in India

India is a prominent market for technology industries, with an increasing emphasis on R&D in the industry. Engineering is a highly innovative field with a bright future ahead of it. Over the last few decades, the industry’s strong growth has drawn the interest of many multinational corporations. Engineering as a specialized subject has exhibited a bright future and has emerged as the most in-demand field, helping to transform the country into a worldwide manufacturing powerhouse.

The Industry 4.0 Revolution is the foundation for the advanced B.Tech Mechanical Engineering Programme with a focus in Smart Manufacturing & Automation. Control systems, internet of things, digital & analogue systems, Computer science (majorly programming, C++, JAVA, artificial Intelligence and Machine learning, Cloud computing and Network Security, Data Analytics), Mechatronics, Robotics, 3D Printing, and Nanotechnology are all included in this multi-disciplinary Programme. This specialty also includes topics like solar energy and its applications, heating, ventilation, and air conditioning, engines and turbines, manufacturing with industrial automation, automobile parts, and computational fluid dynamics designing and thermal, among others.

Industry Revolutions

Industrial revolutions have resulted in a transformation in manufacturing patterns: mechanization via water and steam power, mass production in assembly lines, and automating through computer and information technology.

The first industrial revolution saw the advent of water and steam power and mechanization of production. This was followed by the second one which introduced the electrically powered machines and assembly line production, when mass manufacturing became the dominant style of production in general. The third industrial revolution adopted electronics and devices within the machines, thus leading to developing automation and robots within the manufacturing process.

The Fourth Industrial Revolution is presently being implemented. This is also known as “Industry 4.0,” and it is defined by the use of information and communication technology in the industry. The idea of Industry 4.0 was established by a group of professionals from several professions (such as business, politics, and academia) as part of an endeavor to integrate all manufacturing industries systems to achieve sustainability. Essentially, as a result of Industry 4.0, operations and manufactures will become further efficient and less expensive.

Industry 4.0 encourages manufacturing efficiency by collecting data, making correct decisions. By using the most advanced technologies, the procedures will be easier. This overall consciousness gives Industry 4.0 the most important aspect of artificial intelligent functions.

The Fourth Industrial Revolution, 4IR, or Industry 4.0 conceptualizes rapid change to technology, industries, and societal patterns and processes in the 21st century due to increasing interconnectivity and smart automation

Industry 4.0 is aggregating existing ideas into a different value chain that leads to an improvement in transforming entire value chains of goods life cycles while developing innovative products in manufacturing, involving the connection of systems and things that create self-organizing and dynamic control within the organization.

(The author is Executive Director, Marketing and Admissions Manav Rachna Educational Institutions. Views expressed are personal and do not reflect the official position or policy of the FinancialExpress.com.)