UNIST Research Team Develops Perfect Graphite

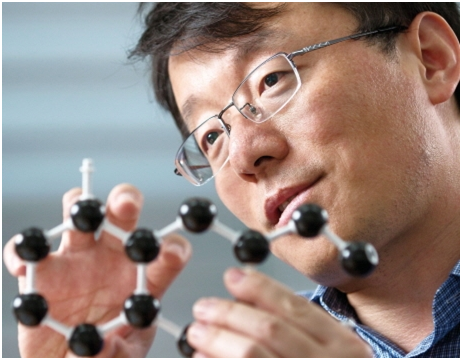

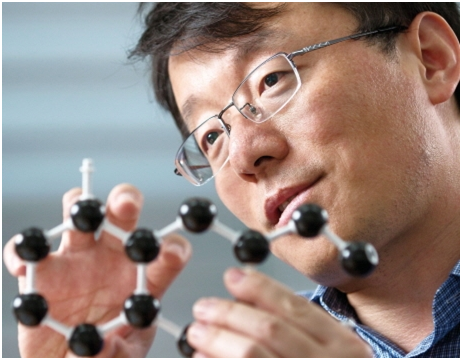

Ulsan National Institute of Science & Technology (UNIST) Materials Science and Engineering professor Feng Ding and his research team succeeded in single-crystal graphite film synthesis with a Peking University research team.

According to the institute, 100,000 layers of graphene are stacked in the single-crystal graphite that is thinner, more flexible and more conductive both thermally and electrically than ordinary graphite and the new development can be widely used in removable and foldable electronic devices.

In graphite, graphene as a flat substance is stacked in layers. These graphene layers are mutually fixed with a very weak force, which means high-quality graphite synthesis can hardly be attained by graphene stacking. The loose inter-layer fixing leads to crushing in the form of multiple crystals, which causes quality deterioration compared to single-crystal graphite.

The graphite film synthesized by the teams has the very perfect single-crystal form unlike natural graphite and existing artificial graphite. The area of the film is as wide as one square inch and its internal impurity content is close to zero. In addition, the gap between its graphene layers is narrower than in any other graphite, which means the highest strength ever. The thickness is approximately 35 micrometers, equivalent to 100,000 graphene layers.

The teams made the graphite by a novel synthesis method in which a solid instead of gaseous carbon material is used. In this method, the material is supplied from behind a special nickel film substrate. The entire surface of the nickel film is flat, which is advantageous for graphite placement and single-crystal synthesis. Details of the research are available on the Oct. 27 edition of Nature Nanotechnology.