Revealed: New battery could last for a week

Image Credit: Gulf News / File

Highlights

- New battery tech invented by ex-IBM scientists dubbed a ‘breakthrough’.

- It uses a solid lithium silicon alloy in the anode — with half the weight and half the volume of traditional anodes.

- It claims a battery energy density of up to 600 Wh/kg and 1,200 Wh/L, twice better than existing Tesla batteries.

- Cost is projected to be less than $100 Wh/kg.

There’s a good chance you’re reading this using a device powered by a lithium-ion battery (Li-ion, or LIB). This ubiquitous contraption has become part of our daily lives.

Now, what if the battery lasts twice as long — no need to recharge your phone for up to a week — and packs enough juice to cover more 1,000 km on a single charge, when used in electric vehicles (EV)?

That is the promise of a potentially revolutionary solution pioneered by an Indian-American scientist, Dr. Devendra Sadana, that could turn the Li-ion battery industry on its head — while significantly improving safety.

Dr. Sadana, an ex-IBM battery guru, is the founder and chief executive of New York-based POSi Energy, whose team has developed high-performance lithium-ion batteries that could redefine an increasingly energy-hungry world.

What we know so far:

What is it?

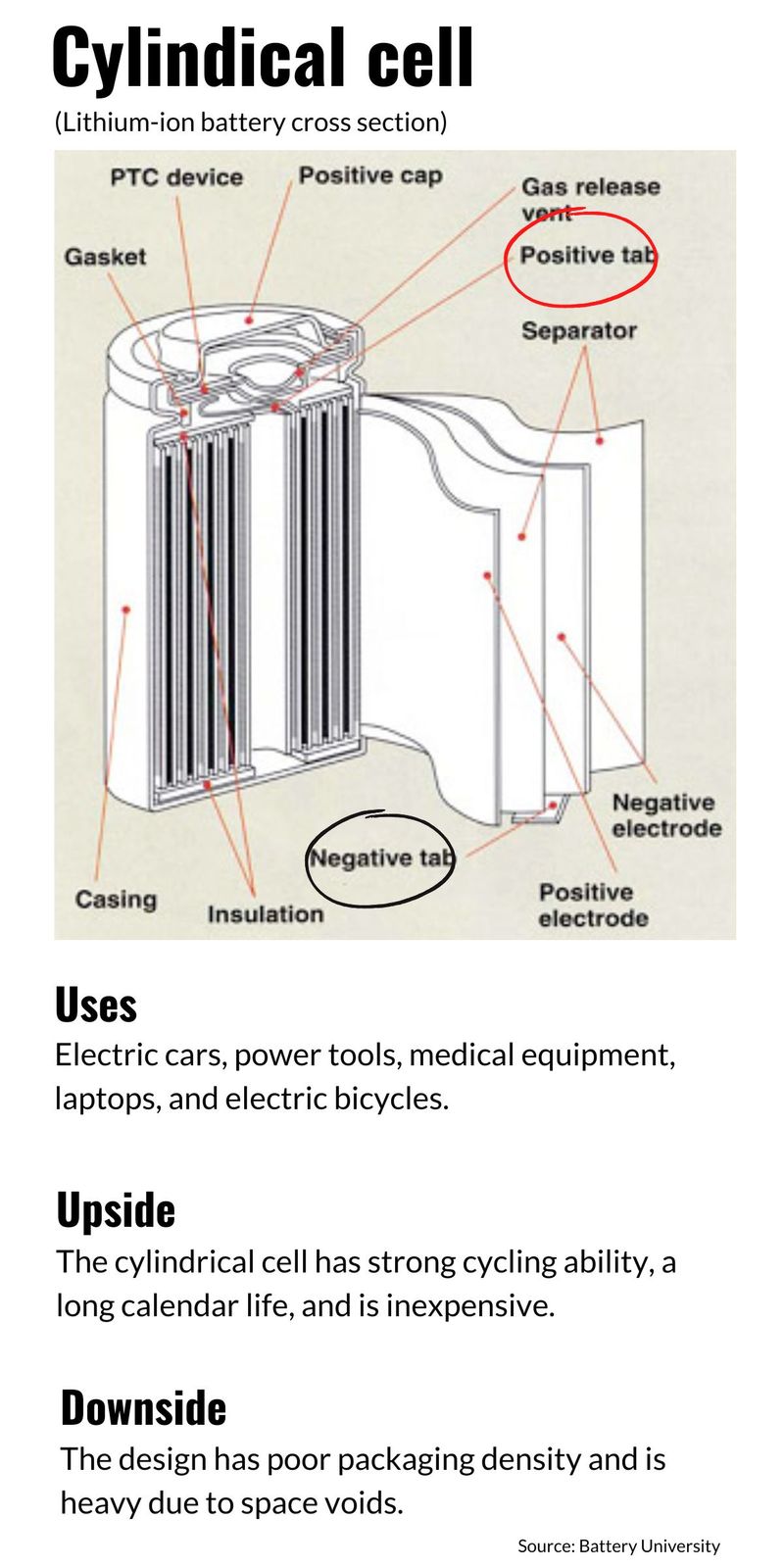

It is a lithium-ion battery — with a twist. A Li-ion battery has three major parts: cathode (positive), anode (negative), and an electrolyte (serves as “catalyst” that promotes the movement of ions from the cathode to the anode on charge, and in reverse on discharge).

POSi’s battery innovation involves a special alloyed (metal made by combining two or more elements) lithium silicon anode. It is dubbed as a “quantum leap” in battery architecture.

What difference does it make?

The technique is claimed to have the potential to safely deliver “gravimetric” energy density of more than 600 Wh/kg and a “volumetric” energy density of 1,200 Wh/L — at the cell level — and without lithium “dendrites”.

This is a major development. Dendrites, which cause significant battery degradations and trigger “thermal runaways”, had been blamed for reports of EVs and mobile devices randomly going up in flames.

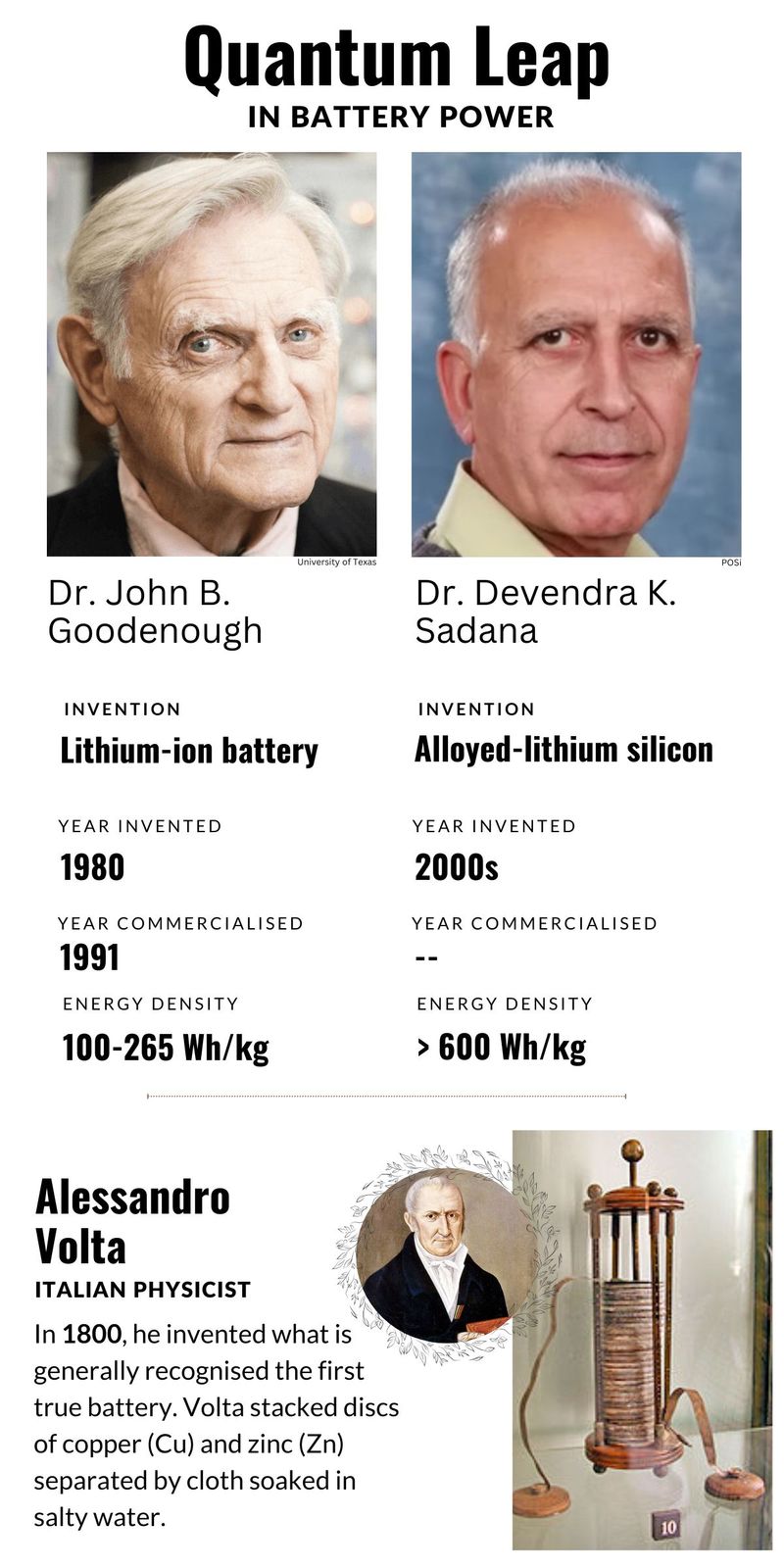

Li-ion battery is also known as the “Goodenough battery,” first developed by researcher Dr John B. Goodenough in 1980. Lithium, the lightest metal, is used in batteries to provide high charge (energy) density. It took another 11 years — in 1991 — when a company, Sony, turned Goodenough’s invention into a product. Years passed before Li-ion batteries were used in laptops, smartphones, power tools, scooties and so on.

Over the years, numerous versions of the battery have been commercialised, such as lithium iron phosphate (LiFEPo4). However, the fundamental Li-ion architecture remains the same. Sadana & Co have changed the architecture at the most constituent parts.

Typically, today’s Li-on batteries have a 1:1.2 cathode-to-anode ratio in terms of unit of measurement. By using POSi’s alloyed lithium silicon anode battery technology, this limitation no longer holds — thus “decoupling” the cathode and anode.

There are fundamental differences between the Goodenough and Sadana batteries.

Instead of using graphite (or its derivative) in the anode, Sadana uses an alloyed lithium silicon. This, he claims, offers two key advantages:

• First: It “decouples” the cathode and the anode in terms of usage ratio. This makes the Sadana battery more flexible, when used in next-generation Li-ion batteries. The amount of energy that can be squeezed into the pack can be pre-defined.

• Second: Its charging power — energy density — is doubled. Traditional graphite-anode based batteries have power densities limited up to 4 to 5 mili-ampere hours per square centimetres (mAh/cm2). Sadana said his solution poses no such limits. “We have already created a cell that delivers more than 10 mAh/cm2”.

Has it been patented?

Yes. POSi has the patent for the new battery. Dr. Sadana, who spent 33 years as IBM researcher, holds about 100 patents in energy-related inventions. The last few years of his IBM stint focussed almost solely on battery research. The technology involves a special lithium silicon anode.

Just as an example, we can use 20 to 50 micron of silicon in the anode, and use 250 to 300 microns of cathode. So we can use that (flexible) ratio now in our favour in terms of how much energy can be squeezed in the pack.

What can the Sadana battery deliver?

The Sadana battery promises to more than double the energy density of batteries used in the latest Tesla EVs. Tesla’s current “4680” cells are rated at 272-296 Wh/kg; the more widely used “2170” cells, has estimated energy density of 263-276 Wh/kg.

We can make the anode as thick as possible and the anode as thin as possible and that’s what gives us a huge advantage in terms of energy density.

Is it available now?

No. Sadana said they have created demonstration units in their lab, and they are ready to license the technology to an original equipment manufacturer that may be interested in scaling it up.

Could it be the panacea to a power-hungry world?

There are a number of battery chemistries competing for capital so they can be mass produced. It remains to be seen whether or not the industry will embrace the Sadana battery.

The technology, architecture, the anode he and his team developed is somewhat different from today’s most widely-used batteries.

“But right now, I cannot see the full potential of the cathode, or lithium batteries… we are the only technology showing to the industry how it can be done. The industry, hopefully, will come forward and try to adopt it. We’ll work with them to make this technology manufacturable. It is a very manufacturable technology,” Sadana said.

One upside, he added, is that POSi’s lithium ion cell architecture is compatible with current battery manufacturing infrastructure, being “integrable into industry-standard cells and can meet the cell-level cost target of below $100 Wh/kg.”

Typical batteries (for smartphones, power tools or EVs) use a graphite for the anode and a liquid electrolyte.

The anode consists of porous carbon (usually graphite), while the cathode is metal oxide.

The most common element used for electrolytes in lithium batteries is a lithium salt solution such as lithium hexafluorophosphate (LiPF6).

Can it be manufactured now?

Sadana said they hope to sign up an OEM battery maker. Dr Sadana said their design is compatible with current battery manufacturing — meaning they can be made using existing lithium ion battery factories.

Being “integrable” into industry-standard cells allows POSi to meet the cell level cost target of below $100 Wh/kg, he said.

What did he do at IBM?

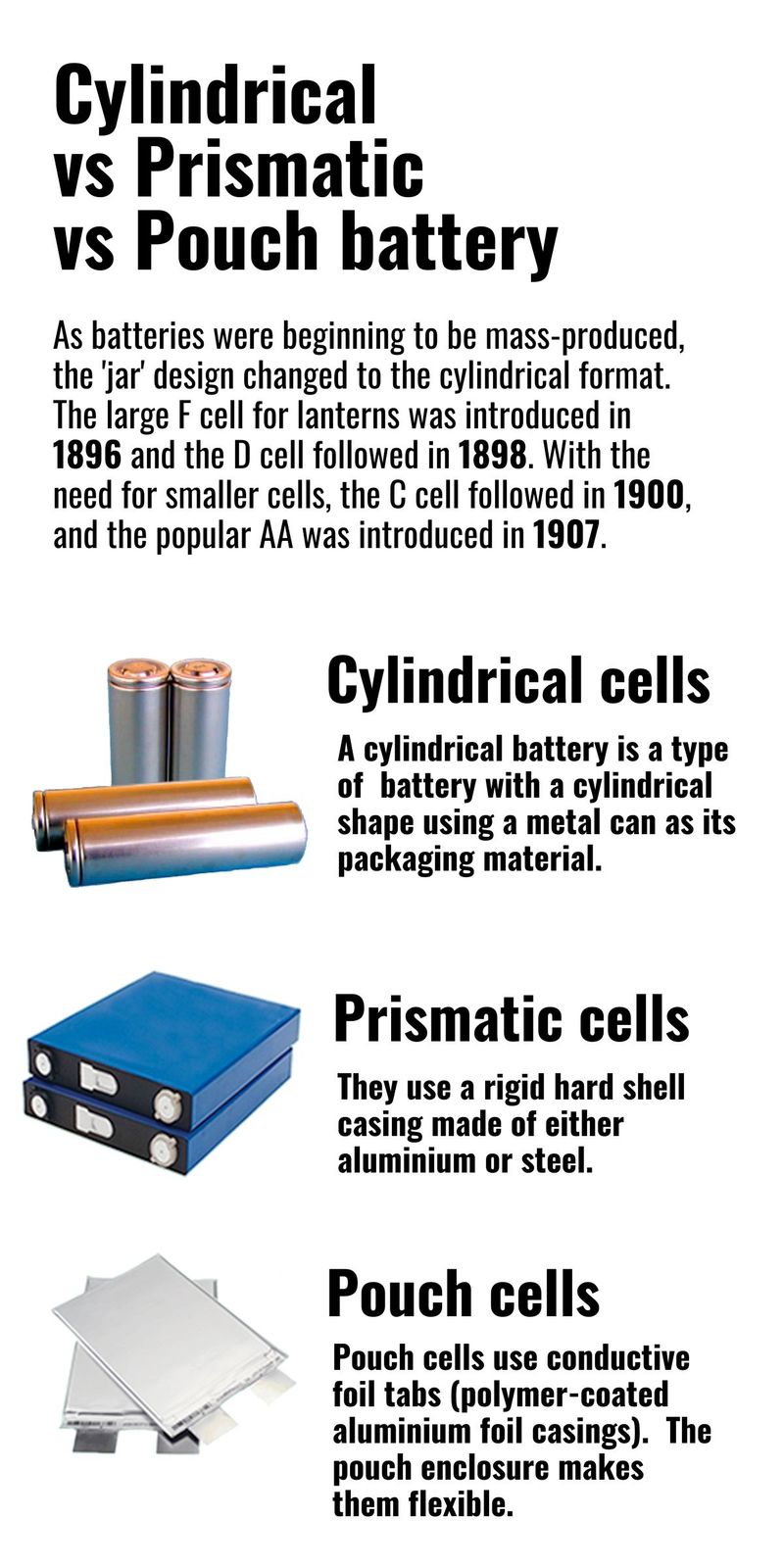

While working at IBM, Dr, Sadana developed a technology by working on pouch-cell prototypes with a capacity fade of less than 0.04% per cycle over 300 cycles with a current density as high as 6 mAh/cm2 by using higher-than-industry standard cathode loading.

After his IBM stint, Dr Sadana founded POSi Energy and acquired all the relevant patents from IBM and company continues to expand its IP portfolio with additional patents.

He is a Professor of Nanotechnology at University at Albany, New York and holds several patents in areas including advanced substrate research in CMOS technology, photovoltaics, optoelectronics, semiconductors, LEDs, Analog Compute Materials & Devices, and Li-ion Batteries.

Prof Sadana is a prolific inventor — with 735 patents to his name, according to opengenus.org, an open-source organisation that aims to make computing more accessible.

After taking a post-doctorate degree at the University of Oxford, he worked as a staff scientist at Lawrence Berkeley National Laboratory in 1979. He joined IBM Research in 1983. Sadana, who was born in India, is a US citizen.

What’s the evidence it works?

POSi has already demonstrated working pouch-cell prototypes with a capacity fade of less than 0.04% per cycle over 300 cycles (in a 4-hour charge/discharge cycle, or C/4) with the current density as high as 6 mAh/cm2 by using above industry standard cathode loading.

Image Credit: Battery University

What limits cathode loading?

Existing battery technology tends to have limited “cathode loading”. Because as energy is pumped into the cathode, capacity decreases profoundly with each increase in charge rate. Ironically, Sadana found that this is actually related to the anode, so his team worked on solving this hurdle.

The higher cathode loading increases energy density, the amount of energy that can be stored and used in a given weight (usually expressed in watt-hours per kg, Wh/Kg).

“If we have a pouch cell, with a good mechanical contact which stays there throughout the cycles, it (capacity loss) would be way below 0.04%,” he told Cleanerwatt. “After 300 cycles, we are not seeing any significant or any measurable capacity loss in capacity (using mechanical clamps).”

“It’s a simple technology, but different in this form factor from what is currently the industry standard.”

Sadana explained their technology is suited more to prismatic cells at the moment. “I don’t see how the industry will be able to fully exploit the limits of the lithium ion battery unless you go in this direction, this approach that we are taking,” he said.

In addition, when the battery is under any kind external pressure, there is a risk of the battery becoming very hot and exploding from overpressure. Furthermore, when a current surges, the battery overheats.

Lithium iron cells also undergo self discharge as the battery is lose their stored charge. Elevated self discharging cause temperatures to rise, which may lead to a thermal runaway, also known as “venting with flame”. During a thermal runaway, the heat generated by a field sell me move to the next sale, causing it to become thermally unstable as well. Thus, a change direction to destroy the entire back within a few short seconds.

34%

Share of Chinese company CATL of the global battery market in 2022.

What does Sadana plan to do with his invention?

The goal of POSi — which Dr Sadana formed in March of 2021 — is to license their technology, similar to the way Apple licenses its technology to Taiwan’s Foxconn.

A POSi deal with an OEM like CATL, the world’s leading battery supplier with 34 per cent of the market in 2022, could deliver to their customers (including Tesla, Hyundai, Peugeot, Honda, BMW, Toyota, Volkswagen, and Volvo) vastly more efficient energy storage products.

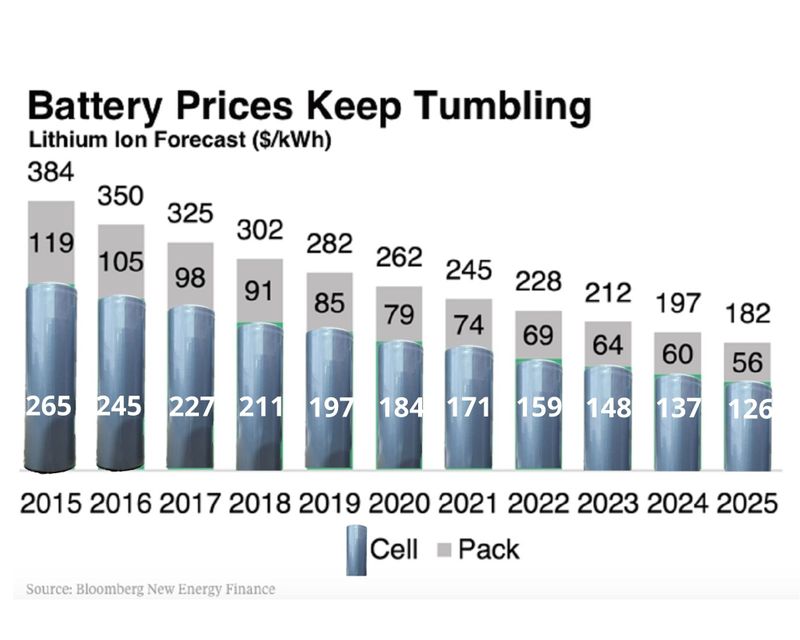

Even as Li-ion demand rises and prices tumble, supremacy in battery tech has emerged as a major item in big-power competition.

Image Credit: Bloomberg / Gulf News

This way, he said, the shift to greener technologies, including battery-powered vertical-takeff-and-landing planes, will accelerate.

In terms mass production, Sadana told Cleanerwatt: “Once production starts, it will hopefully fly.”