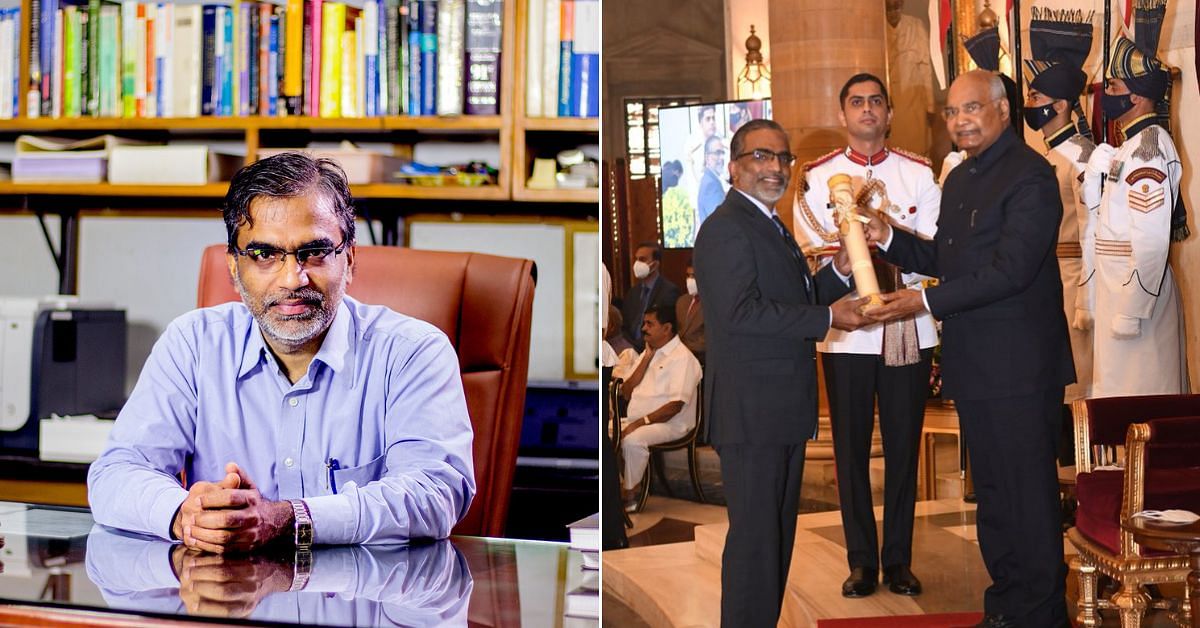

Dr Thalappil Pradeep, an institute professor at the Department of Chemistry, IIT Madras, received the VinFuture Prize at the award ceremony in Hanoi, Vietnam, last month. This isn’t the first time Prof Pradeep has been recognised for developing technologies delivering clean water to over 1.2 crore people in India. He is also the recipient of the Padma Shri, Nikkei Asia Prize, and Prince Sultan Bin Abdulaziz International Prize for Water, among others.

An award sponsored by the Vingroup, the largest Vietnamese conglomerate, the VinFuture Prize honours breakthrough scientific research and technological innovations that create meaningful change in the everyday lives of millions of people. Along with this prestigious award, innovators like Prof Pradeep also received prize money of $500,000.

What has Prof Pradeep done to receive such recognition globally? His research group at IIT Madras discovered affordable and sustainable nanomaterials that can remove impurities — like arsenic (primarily), manganese, uranium and iron — from groundwater and produce clean water.

Employing simple designs, his retrofitted technology provides a means to purify groundwater at a low cost to reach millions of impacted households. In remote areas, this technology is more advantageous because it does not require electricity on its own. However, the larger rural water supply system to which this technology is retrofitted to does require some electricity for pumping, distribution, monitoring and control.

Understanding the basic technology

Before addressing other impurities in our groundwater, Prof Pradeep’s technology began by finding ways to remove arsenic — one of the most commonly found impurities in several States. Exposure to arsenic from drinking water causes heart disease and diabetes, and may even cause death by cancer. But there are problems in existing purifier technology regarding arsenic:

1) Arsenic exists in two ionic forms — Arsenic (3+) and Arsenic (5+). The general methods of removal by materials do not remove both of these ionic forms effectively. Certain methods remove As+5 more and less of As+3. As a result, you still have arsenic in the water.

2) The kinetics of arsenic removal may not be fast enough for community units which need larger flows.

3) Arsenic removed by a material may not stay on it causing recontamination of water.

“We addressed these problems with materials, i.e. our technology removes both As+3 and As+5 effectively, the kinetics of removal is fast at any kind of flow rates from two litres or one million litres a day, and the removed/absorbed arsenic does not get leached out from the material,” explains Prof Pradeep, in a conversation with The Better India.

“If it’s possible to do it at a cost affordable to people, the technology gets adopted. These materials are also sustainable because they’re not using additional energy for their production and they do not cause recontamination of water in the course of its production after its useful life,” he adds.

Besides arsenic, the research group at IIT Madras also found that in different regions across India, there are also manganese, uranium, chromium, mercury and fluoride contamination of groundwater. With a few modifications, they found that the same nanomaterials materials can remove or absorb these impurities as well. “Our technology can effectively address contaminants of relevance to those water samples and can purify a maximum of two million litres a day,” he says.

But what are these affordable and sustainable nanomaterials?

“These materials have to be locally available and sustainable, and I do not want to work with any synthetic material to cause additional problems. What we have done in this particular case is to produce ‘metastable iron oxy-hydroxide’ in its nanoscale form, and this removes both As+3 and As+5 efficiently,” explains Prof Pradeep.

“When I got into the water space, I set a target a long time ago — to produce 5 paise/litre of clean water conforming to World Health Organization (WHO) norms. This cost includes equipment (capital), consumables and maintenance together. Today, the price is 2.5 paise (or less) per litre of clean water,” he adds.

Advancements in technology

The discovery and practice of this technology aren’t recent. In 2013, his team developed an affordable nanotechnology-based water purifier to address arsenic contamination and other chemical or microbial impurities. Since then, there have been major advancements.

“In terms of material, what was used earlier was also iron oxy-hydroxide, but with modifications, today they’re also handling uranium and manganese. These nanomaterials are fitted into devices that are more compact in appearance. Typically, any new technology for water takes about eight years to transition from the laboratory to the field. Our technologies in the field today are significantly better than the ones we made in 2015,” he says.

“But what has also been very new in this area is the capability to measure arsenic at that concentration by hand-held devices. These devices are going to the field very soon. Another new development is to ‘digitally make water available’ — in the sense that you collect data and control these devices through automation. We have implemented many such systems,” he adds.

Requires no electricity

Producing this technology does not require electrical heating and organic solvents.

“We produce these nanomaterials in water with naturally available materials and in the absence of heating, there is no energy spent there. The process of utilisation is absorption, which doesn’t require any energy. The energy requirement is in terms of water pumping. Water has to be stored in an overhead tank or flowed through a pipe which requires pumping. The process of removing arsenic or uranium itself does not involve any energy,” explains Prof Pradeep.

“For a given community water purifier, there will be an overhead tank. In that rural water distribution line, we install a purifier unit. Input water goes into the purifier and output water goes into the distribution line. This treatment unit will occupy a land area of one or two cents of land, or slightly less. It’s positioned on a cement platform which can be erected in typically three to four days. Building the larger civil structure, however, will take some time depending on the local contractor, and it’ll take a few days for cement curing,” he adds.

His technology requires conventional power for automation, but this can also be done with solar energy. Additional power requirements are only for water to reach these purifiers.

Process of implementation

Typically, a state government identifies a state or a district where it has a groundwater contamination problem. Buying and installing a unit of this technology costs several lakhs of rupees depending on the size.

“We have several startups and established companies incubated at IIT Madras who undertake the responsibility of implementing our technologies in the field. As an institution, we are also ready to assist in the installation process. We are not on the field directly but take up an advisory role. These companies are also free to interact with governments directly,” explains Prof Pradeep.

Take the example of Punjab, where community water purifiers have been set up in 97 rural locations in 2020-21 with capacities ranging from 35 KLD to 1,000 KLD (kilolitres per day). There were more units installed earlier.

This water purifier is called AMRIT (Anion and Metal Removal by Indian Technology or ‘nectar’ in Hindi). All these plants have been installed by Hydromaterials Pvt. Ltd, a company incubated by IIT Madras which specialises in water purification.

The plants are cleaned once every 15 days through a process called ‘backwash’. When the nanomaterials which absorb the impurities reach saturation capacity, the active materials are replaced, and the state has arranged for the safe discharge of this material.

“Saturation of the media depends upon arsenic concentration in the input water, amount of water passed, and other contaminants in the water. Generally, in community water purifiers, it takes about two to three years to reach saturation point. To address this concern of safe disposal and spent media, the Government of Punjab has identified safe disposal sites as per protocol. They maintain such sites. Saturated media conform to guidelines in terms of leaching,” claims the professor.

The largest plant in operation is in Chaudhri Wala, a village in the Ropar district. Here’s a 1,000 KLD plant delivering clean water to about 650 households, almost 4,000 people at 70 LPD (litres per day) per person. These community-based projects are monitored centrally with IoT technology.

However, there were challenges in implementing the nanomaterial-based arsenic and iron removal technology in community water purifiers.

Speaking to The Better India, Jaspreet Talwar (IAS) — former Principal Secretary, Water Supply and Sanitation, Government of Punjab, between 2017 and 2021 — elaborated on these concerns. Today, she serves as Principal Secretary, Higher Education and Languages, and Principal Secretary, School Education, Government of Punjab.

“There are costs involved in not just the initial installation of the technology but also for replacing the media once it reaches a saturation point. These community-based arsenic and iron removal plants—retrofitted into the existing water supply system—are a very good idea but require money to sustain periodical media replacement, running costs including routine upkeep and power bills year after year,” says Talwar.

Who’s going to give the money for that? How do you sustain it?

They needed to look at long-term solutions. Where the communities were sizable, the idea was to obtain contributions from the wealthier residents in addition to the money coming in from the tied Finance Commission grants of the Government of India for water and sanitation in Punjab.

“We felt that some percentage of these grants could go into an account which could sustain these projects. We eventually set up the Water Quality Kosh, a ring-fenced bank account, and the idea was to put some money into this from State funds, CSR funding, private donations, and contributions from the affected residents who could afford to contribute,” she explains.

Despite coming up with these mechanisms, state officials approached the researchers at IIT Madras to develop a cost-effective and more sustainable solution which could be individual household based. After all, individuals look after their own assets well.

Prof Pradeep’s team came up with a household arsenic water filter consisting of two steel drums which have candles that contain the same nanomaterials. These candles help in the adsorption of arsenic and iron from groundwater to produce potable drinking water.

These purifiers work on gravity and do not require power to operate.

“The state government initially distributed household water purifiers to each household in 54 arsenic-affected villages for free to encourage greater community-level adaptation of the technology,” explains Talwar. Residents from arsenic-affected areas of rural Punjab could meet their individual drinking water needs from these household purifiers while their other requirements were met by the regular piped water supply of the village.

“Running cost of these household nanomaterial-based purifiers is negligible. After all, each household does its own maintenance. The requirement to replace the media candles will be there in a few years, for which the government may again need to step in to provide support to these households or provide for these candles through the market.” she adds.

The researchers at IIT Madras especially helped design these prototypes along with the Department of Water Supply and Sanitation, Punjab.

They also supported the department by designing and implementing an IoT-based monitoring system for large arsenic and iron removal plants (AIRPs) installed across rural Punjab. Also, they set up a grievance and monitoring call centre for AIRPs and individual household units.

This system allowed officials to check telephonically whether people were using these units given that a unique number was engraved on each purifier distributed and a central record was maintained household-wise.

“After addressing a few in-use issues, these AIRPs and filters began to work well. This academia-government collaboration did help mitigate the environmental and social problems. Yet a fresh assessment will be needed to gauge the long-term sustainability of this technology and its health outcomes,” she adds.

Recognition

“Most of the recognition I have received is for fundamental science. While doing fundamental science, it’s also possible to do applied science. My message to students is that you can work in both fields parallelly because it’s imperative to solve problems like these,” says Prof Pradeep.

Meanwhile, Prof Sir Richard Friend, VinFuture Prize Council Chair, said during the award ceremony, “The VinFuture Prize Council is honoured to award brilliant scientific minds for their outstanding innovations. It is my hope that the prize will contribute to promoting scientific research, creating more breakthroughs that can positively impact society, and helping build a better life for everyone. This is a mission and responsibility that we take very seriously.”

This is Professor Pradeep’s hope as well.

(Edited by Pranita Bhat)

(Images courtesy IIT-Madras, Professor T Pradeep, Pradeep Research Group)