Innovative risk-assessment tool for produce industry continues advancing

WEST LAFAYETTE, Ind. — Mohit Verma’s research team at Purdue University has developed innovative paper-based, rapid-result tests for bovine respiratory disease and COVID-19. Now the researchers are adapting their technology for produce safety risk assessment.

“We’ve already done some preliminary tests out in the field, which will be published in the next few months,” said Verma, assistant professor in Agricultural and Biological Engineering and the Weldon School of Biomedical Engineering. We’ll be refining our technology a bit more so that it’s easier to use.”

The technology uses biosensor technology to detect DNA from Bacteroidales, a fecal microorganism found in swine, poultry and cattle, as a marker for the contamination of fresh produce. Most foodborne pathogens linked to fresh produce, including E. coli and Salmonella enterica, originate in the intestines. That means measuring fecal contamination can suggest the risk of produce contamination.

Verma’s team has received a two-year, $394,500 grant from the Center for Produce Safety in Woodland, Calif., to continue developing the technology in 2023. The center funded an earlier phase of the project with a two-year grant of nearly $400,000.

Research results from the earlier grant have appeared in the journal Food Microbiology. Another article that recently appeared in Trends in Food Science & Technology reviewed various biosensor technologies that could be used for detecting bacteria in fresh produce.

The researchers found, after talking with their industry collaborators, that few of the most recent technologies are being deployed in the field for fresh produce safety. Currently, workers in the leafy greens industry collect samples, send them to a lab and then wait for results.

“Right now, the gold standard is still the Food and Drug Administration procedure, which is growing bacteria in media. And it’s been like that for 50 years or so,” said Jiangshan Wang, the lead author of the Food Microbiology paper and a PhD candidate in Agricultural and Biological Engineering and the Birck Nanotechnology Center.

The assay that Verma’s team has developed is called loop-mediated isothermal amplification (LAMP). It yields results in the field in less than an hour. That saves valuable time and effort for produce companies, which typically have only seven days after harvest to get their fresh leafy greens to market before they begin to spoil.

“Every day, every second matters,” Wang said. “If we can have this ready in the field, we can save growers at least a couple of hours or days.” The LAMP assay is designed to be user-friendly for large-scale use.

The Purdue team will test the assay’s versatility at three locations during two different seasons of the year. One test site will be in Indiana, close to animal operations where nothing is being grown. The other two locations will be fresh produce industry sites close to animal operations where the researchers can map the risk gradient.

The researchers will also collect data from on-site weather stations to learn how local conditions and air quality affects contamination risk.

“The goal is to make it easier to do the assay,” Verma said. “It will produce a color-based result, which could be analyzed by the naked eye. Or if you want to quantify your information, it could be automatically analyzed using a built-in imager.”

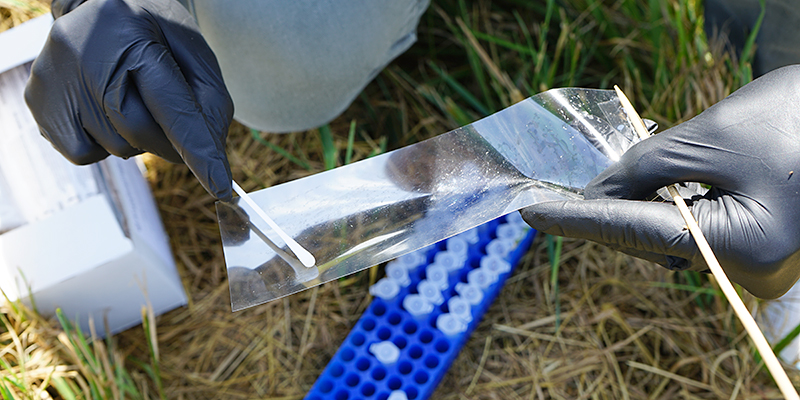

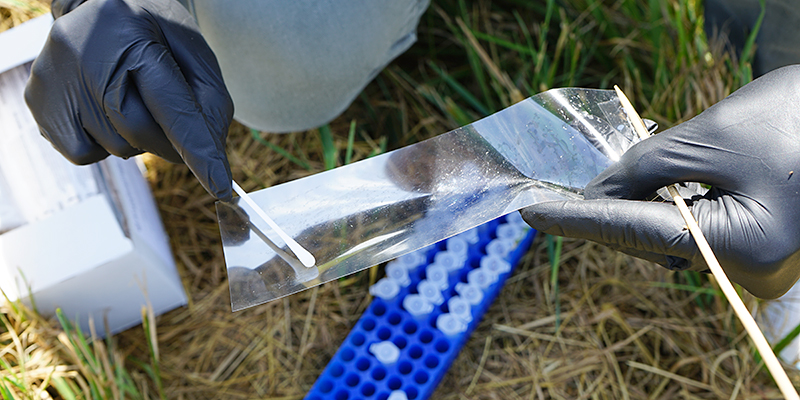

Lab-based assays often involve collecting and washing leaves, then sending them to a lab. At first, Verma’s team swabbed lettuce leaves to see if they held any contaminants. But the grooves in the leaves foiled that sampling method.

Then the team’s industrial partners suggested a simple fix. The researchers now use plastic sheets to collect whatever happens to land on them. These “collection flags” provide easily repeatable results along with location data. The flags can be planted in particular locations with unique identifiers.

“Do the assay on each flag, and then you have spatial data,” Verma said.

The Center for Produce Safety connected the Purdue researchers to their advisers from the fresh produce industry.

“They make sure we as scientists know what the problems are,” said Verma, who launched a startup, Krishi Inc., to solve those problems. “We go for problems that will have an impact. And most of the projects that we’ve worked on have started with stakeholder conversations.”

Krishi has licensed other LAMP-based technologies from the Purdue Research Foundation Office of Technology Commercialization for the development of veterinary diagnostic applications.

Writer: Steve Koppes

Media contact: Maureen Manier, mmanier@purdue.edu

Source: Mohit Verma, msverma@purdue.edu

Agricultural Communications: 765-494-8415;

Maureen Manier, Department Head, mmanier@purdue.edu