Outdoor Retailer 2023: Fine examples of ingenuity, science, lifestyle creativity, bootstrapping, cultural integrity, authentic eco-consciousness in show’s return to SLC

This month’s just concluded Outdoor Retailer show, marking the event’s return to Salt Lake City after five years, highlighted a good representation of creative entrepreneurship and collaborations. Even for those who might not be avid outdoor recreation participants, there were plenty of ingenious, artful, elegant product lines and innovations, which suggest that the tent of the outdoor industry market can be greatly expanded to consider virtually every lifestyle, aspiration and appeal. The next Outdoor Retailer show will be June 19-21 at the Salt Palace Convention Center. The Utah Review highlights several examples.

PAKA APPAREL

A paragon of a bootstrapping case for aspiring entrepreneurs, Kris Cody transformed the unforgettable impression of the hand-woven alpaca wool sweater he purchased nearly eight years ago from a Quechua woman during a trip to Cusco, Peru into Paka Apparel. The company also won an Innovation Award at this month’s Outdoor Retailer Show in Salt Lake City. The award was given for Paka’s patent-pending PAKAFILL® insulation, which has consistently tested as staying warmer and drier than customary synthetics in lightweight puffers.

In 2015, prior to beginning studies for his neuroscience degree at the University of Virginia, Cody spent his gap year traveling through South America. Back in the U.S. and on the UVA campus, Cody noticed that whenever he wore the sweater handwoven by a Quechua artisan, many of his friends commented on how it felt much softer than a cashmere or merino sweater.

The compliments stuck with Cody and fueled a move that would impress any seasoned entrepreneur. Completing his freshman year, he returned to Cusco, wondering if he could turn his dream of bringing traditionally-made Incan apparel to the U.S. “I bought a ticket for a one-way flight,” he says in an interview with The Utah Review. He soon established a network of artisan weavers, many of them women. As he explained in a UVA feature from 2017, “Last summer it was just a dream. I was designing the initial round of sweaters. Every single morning, I’d go over and meet with the Chaskis, a family of weavers outside Cusco. We’d cook eggs together and work on prototypes. It was really a shared vision.”

In addition to the apparel prototypes he developed with the input coming from the Quechua artisans, he realized that as much as the craft was an anthropological language of indigenous cultural expression and preservation, it also was a resilient means for supporting economic and educational empowerment for the weavers and the alpaqueros, the Peruvian families in the Andean highlands. The families oversee relatively small herds of alpacas, usually between 60 and 90. But, as Cody adds, while it takes four sheep to shear enough fleece for a single sweater, one alpaca can provide enough fleece for four sweaters. Alpacas also must be sheared at least once a year, which protects the animals from risks including overheating, becoming immobilized, being susceptible to predators and parasitic infections.

When Cody returned to the U.S., he collaborated with friends to create a website to feature what became the first line of Paka sweaters. He won a spot in UVA’s i.Lab summer incubator to guide the founding of the company. Like many millennials, he comprehended the potent reach of social media and prominent influencers. They included pro surfer Leah Dawson, U.S. snowboarding team member Chase Josey and Chance the Rapper. In 2017, the company was launched with an instantaneously successful Kickstarter campaign. And, yes, he completed his neuroscience degree.

More importantly, Cody structured Paka to provide direct economic returns to the weavers, who sign each piece of apparel made. More than 100 Quechua women are employed and are paid quadruple the typical family living wage standard in the region. The company also has started a university scholarship program, by giving six awards covering full-ride costs for Peruvian women. One of the board directors is Nilda Callañaupa Alvarez, a Quechua weaver who established the Center for Traditional Textiles of Cusco more than a quarter of a century ago. Cody says that it was important to ensure the weavers have a voice in ensuring the cultural integrity of Paka’s apparel and products and Alvarez is overseeing those efforts.

Cody’s scientific background and his experiences in the Andean Highlands have expanded into other products for the company. Focusing on the challenge of making products that avoid the micro plastics contamination problem, the company now offers lightweight puffers which are packed with alpaca fiber — the award-winning PAKAFILL® insulation — encased in a water-resistant shell made with certified recycled polymer. Like every other Paka apparel product, the new puffers have QR codes to trace back to originating sources.

LIMBER BOWS

Handcrafted products signaled a definite trend at this month’s show, particularly for the ingenious process that led to their creation. A Bozeman, Montana musician who is part of the Storyhill folk duo, John Hermanson also plays violin. Thus, this segues to the impetus which led him to create Limber Bows, a versatile, virtually all-purpose set of trekking poles. He started by working in his garage and a critical mass of interest has been steadily building about his invention.

Any musician who plays a stringed instrument with a bow can relate to the underlying physics and benefits of Hermanson’s invention. Fashioned in seven layers of materials, the poles comprise layers of woods such as ash, hickory and ipe, fiberglass and carbon fiber.

In navigating the steepest ridges of the North Cascades range, Hermanson says he became obsessed with the project. He wanted to fashion poles that would hold up his weight while still being flexible enough to move through rugged terrain, without exerting to the extent of losing the stamina needed for hikes. He eventually discovered that the poles were effective for hikes as long as 20 miles. “I could feel my oxygen levels were better and even at the end of a long hike, I feel like I am full of energy,” he adds, in an interview with The Utah Review. Hermanson put the proper punctuation on the point, as he was wearing a pair of the smartly engineered pair of sock shoes from Skinners Footwear (which is featured elsewhere in this roundup).

He wrote about the core significance of the progenitor of Limber Bows at his website:

I still have the stick I found that day under 5 inches of ash. It was burned into an elegant semicircle by the Wolverine Creek fire of 2015. It travels with me in my VW bus everywhere I go and works great as a frame to twist a string of USB LED lights around so I don’t have to worry about my dome light draining the battery. It also sits inside the “hot box” with every bow I build, for the final stage of the 24 hour curing process. It’s a small ritual I perform to recognize the lineage every new bow belongs to, a reminder that each new prototype is the result of lessons learned from all its predecessors, reaching all the way back to this found original.

Think of how a trained violinist uses good bowing techniques to produce the most ideal sound, while thinking about the appropriate speed, position, force and placement used with the bow. Likewise, the poles’ recurved bow design, which stand at a person’s shoulder height, will give the user the benefit of more limber movement and spring in their step. Consequently, this enhances the endurance capacity of a hiker or outdoor recreation user. To wit: Hermanson’s father has been chair of the physics department at Montana State University.

Hermanson says he worked through prototypes to find the most ideal design. “My father says that the bows allow him to exercise three times longer than before,” he adds. He says that while he initially designed the product for hikers and trekkers moving across steep, rugged terrain, the bows have lots of purposes for use, including skiers, yoga practitioners and those who are looking for conditioning regimens as well as those who are in physical therapy or rehabilitation.

Hermanson asks for testimonials from customers who have purchased the bows. A trail yoga enthusiast from St. Paul, Minnesota shared her experiences about using them on a hike through a steep ravine in Michigan: “I can feel the bows vibrating and moving in sync with the flex and release of my muscles. They keep my stride steady and rhythmic, anticipating the contours of the terrain. And when I stop to catch my breath, I lean back on them to release my spine and look at the sky.” She added that the sensation was like surfing waves, practicing yoga or playing a bass guitar.

ALLIED FEATHER + DOWN AND FUZE BIOTECH

For more than 35 years, Allied Feather + Down, a family-owned business based in California, has anchored its leadership in the industry for its practical advancements in products, which address the desired standards for sustainability, traceability, environmental conservation, accessibility and climate change. It pioneered two of the most far-reaching programs in quality assurance and social responsibility in the outdoor recreation industry: Responsible Down Standard (RDS) and Track My Down.

At its most recent Outdoor Retailer appearance, Allied Feather + Down in partnership with FUZE Biotech won an Innovation Award for ExpeDRY, acknowledged as the first widely applicable chemical-free, fast-drying down insulation.

The collaboration with FUZE, which is based in West Valley City, Utah, is notable. FUZE has developed, extensively tested and made practical applications available of a technology free of chemicals, which can be applied to any surface of fabric to protect against bacteria, pathogens, mold and virus contact. For example, a five gallon jug of the ExpeDRY solution can be used to treat one million yards of fabric. This will practically eradicate any harmful risks of side effects for the individual and the natural environment.

Unlike previous manifestations of nanotechnology, which periodically have fallen short of their expectations in delivering sustainable results, FUZE uses a high energy method to produce nano-particles for specific purposes. Researchers have discovered that nanoparticles are not ionic and in FUZE’s lab work, it has been discovered that these smallest of particles also exhibit anti-microbial features.

In a demonstration of the process behind the ExpeDRY technology at the FUZE facilities, visitors also learned about progress on a new topical therapeutic treatment for cystic fibrosis, which is now in the phase of being reviewed for approval by the U.S. Food and Drug Administration. The company started the project with supporting grants from the Cystic Fibrosis Foundation, the University of Washington and a children’s hospital in Seattle to see if the technology would be effective in killing pathogens, especially those connected to cystic fibrosis.

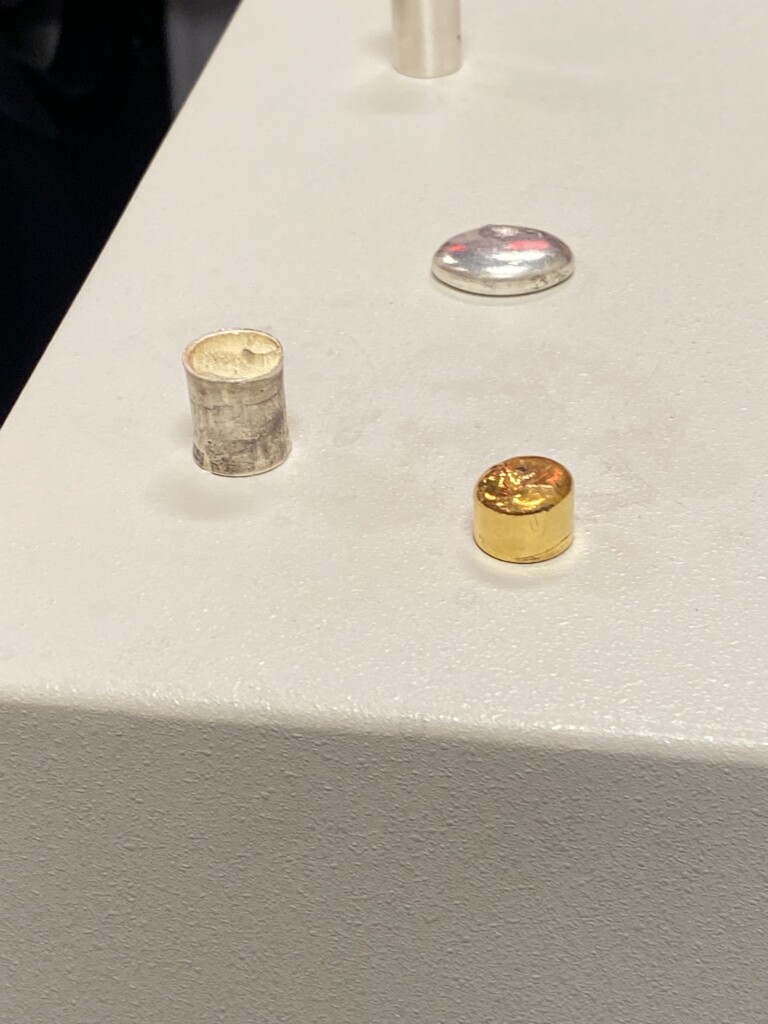

The discussion clarified the bridge which leads to how ExpeDRY developed. It was initially discovered that treating quality fabrics with a solution would be durable enough to give the materials anti-microbial features that would last through dozens of washes. In the initial prototypes, scientists were experimenting with silver particles combined with gold that were safe enough to use without compromising the environment or humans with any deleterious effects. But, they happened upon discovering that permanently bonded gold nanoparticles were effective to achieve the desired results. Thus, the gold nanoparticles set up an electro-static barrier, which enhances the hydrophobic characteristics and interacts with water’s hydrogen bonds. This means that droplets of water can be broken up before saturating the garment while preventing humidity from forming additional droplets.

FUZE Biotech, Allied Feather+Dpwn ExpeDRY.

So for those performing or working in wet weather, the drying time is substantially reduced with this application being used in the down material cluster. The science shows that these gold bonded nanoparticles build up the evaporation of water without requiring heat (a clothes dryer). In conventional water-resistant treatments for down, the applied solutions function like a hydrophobic agent, which allows water to bead and thus the apparel can stay drier for longer. But, once the fabrics are saturated, the conventional treatments no longer are efficacious for drying. ExpeDRY’s tests have replicated the following results consistently: the larger evaporation rate outweighs the benefits of conventional fabric treatments and treated garments dry nearly twice as fast as those saturated with other treatments

The implications could be far reaching, extending beyond outdoor recreation and sports performance to the laundry, bedding and linen services at hotels, resorts, hospitals, universities and other large institutions.

In a prepared statement, Daniel Uretsky, president of Allied Feather + Down, emphasized the collaboration with FUZE. “Using their incredibly knowledgeable and unique approach to innovation and dedication to sustainability, we are finally able to realize our quick-drying product,” he said. “This is a potential game changer for the European market that relies on condenser dryers, which have always made down insulation difficult to care for and dry properly.”

Customers will see products from Artilect, Jack Wolfskin and other outdoor recreation brands available, especially later this year, which will be treated with ExpeDRY.

SKINNERS FOOTWEAR

Based in the Czech Republic, Skinners Footwear already had anchored itself in the minimalist footwear market across Europe. But, the Outdoor Retailer show this month was the ideal opportunity for early adopters in the North American market to be introduced to the company’s newest lines of sock shoes and sneakers. These shoes emulate the barefoot feel that a growing number of outdoor recreation enthusiasts desire, as hikers, runners and trekkers. In fact, as mentioned earlier, Limber Bows’ John Hermanson sported a pair of Skinners’ sock shoes at his exhibitor’s booth.

It is easy to admire the compact elegance and effective functional protection of the footwear Skinners offers. In an interview with The Utah Review, Michal Presse, chief marketing officer, says the focus is on quality without sacrificing the minimalistic objectives. There are just 13 compounds involved in the making of the footwear, which reinforces its durability and holds up to rigorous outdoor activity. “No gluing. No stitching,” he says. “Our focus has shifted from the objective of the individual adapting to the shoe to the more satisfying outcome of the shoe adapting to the individual’s needs. In other words, it’s feet-first design.”

The sock shoe’s features include improved moisture wicking capacity, so feet will stay dry as well. The ultra-thin polymer sole layer, measuring just a tenth of an inch in depth, has been designed to last for up to 500 miles. The use of synthetic and natural fibers are compounded to fit to anyone’s feet.

Already, Skinners Footwear has sold more than 700,000 pairs in approximately 100 countries in six years, which makes the North American entry a potentially auspicious move. The Outdoor Retailer show became a showcase for two of the company’s newest product lines: the Compression 2.0 and Walker series. The Walker series of sneakers is competitively priced, comparable or actually lower than most other brands familiar to the North American market. It is their stylish minimalistic design which fits properly in the consumer equation. The shoes are made with Italian leather and a zero-drop flexible rubber sole. Presse adds that enough space is considered where the toe box is so that toes can move freely in each step. The soles are constructed so that the movement then allows an individual’s muscles and tendons to open up naturally, which is optimal for leveraging the benefits of physical activity and exercise, indoors or outdoors.

Eco-conscious manufacturing considerations are essential in meeting zero-waste technology, Presse adds. The polymers are Swedish in origin, the fibers and leathers come from Italy and the sole comprises recycled materials.

GRAND TRUNK

Now in its third decade of operation, Grand Trunk is now a Utah company brand after relocating from its original Chicago metropolitan area home in 2020. In the couple of years since it moved to Utah, as Paul Asay explains in an interview with The Utah Review, the company – which produces product lines of hammocks, chairs, stools, blankets, pillows and miscellaneous accessories for outdoor recreation – has added 10 items. It also has splashed its product lines with creative whimsy, by expanding design and color options to cover a broader spectrum of lifestyle aesthetics, styles and desires.

And, as with many of the exhibitors at the Outdoor Retailer show, Grand Trunk used its venue to showcase products, which could suit everyone’s preference, regardless of how intense or casual their preferred form of outdoor recreation might be. The chairs and stools, for example, are compact and collapsible so they can fit in any passenger car or trunk. They are perfect for soccer games or parades, For those who cringe at the prospect of pitching a tent for outdoor sleeping and relaxation while camping or at home, there is the Evolution Hammock. Asay says this hammock incorporates the purposes of a sleeping bag into a hammock without the need for underquilts or overquilts. The hammock includes a baffled insulation underquilt, which prevents the individual from being chilled when temperatures drop. Add a pillow and a favorite stuffed animal and Asay says that the hammock can become as appealing and comfortable as any sleeping bag or cozy bed. The hammock also can be transported easily in any passenger car and comes in at just six pounds.

Venturing into the artistic design realm, Grand Trunk also offers Color Block Collection options in patterns and colors for its hammocks. One is a fabulous green design inspired by the Bauhaus style. Others have included limited edition offerings of Ugly Sweater, Fungi Field and Flamingo Print.

Asay says that the products carry a lifetime warranty. Durability is critical for gear quality and it is Grand Trunk’s objective to ensure that customers are motivated to keep their products and to avoid thinking about tossing them when they ultimately end up in the landfill.

SHWOOD EYEWEAR

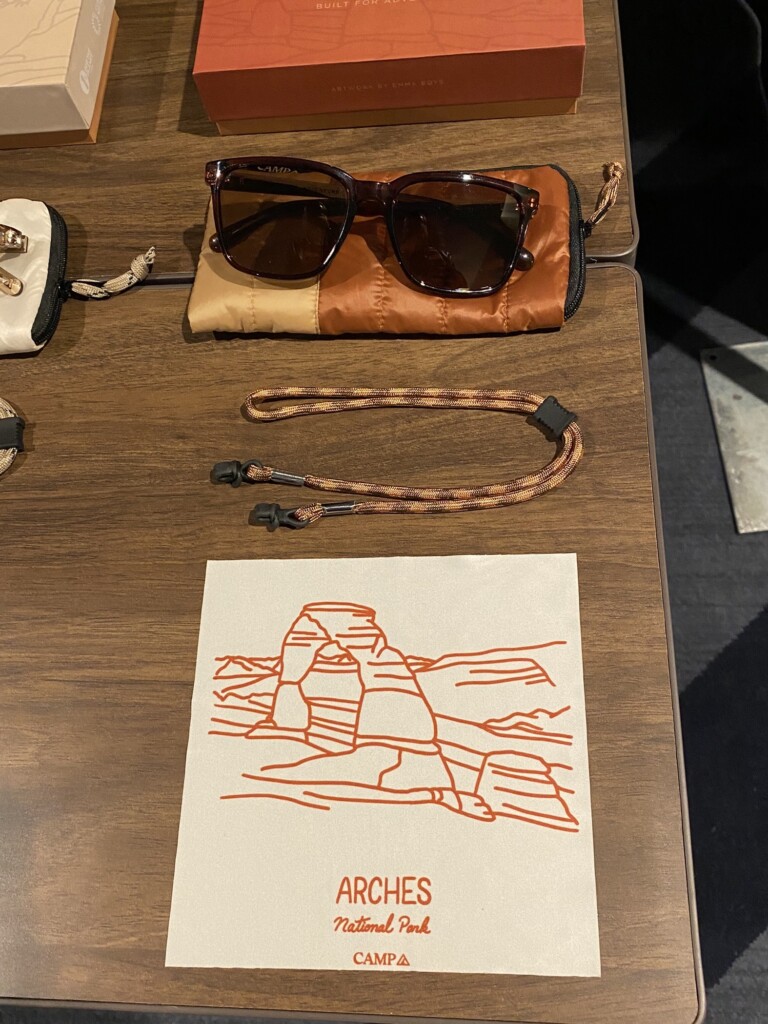

In celebrating some of the nation’s national parks, Shwood Eyewear recently introduced the CAMP collection of sunglasses, in which a portion of the proceeds (5%) is given directly to the national park featured in the respective product. The four parks featured in the collection include Arches National Park in Utah, as well as Joshua Tree, Glacier and Crater Lake. The Crag product for Arches includes clay and walnut components, along with a chamois cloth featuring a line drawing of one of the park’s iconic images.

The wood inlays are a smart complement to the eyewear, which is made from plant-based bioplastic. Other features are polarized lenses to offset glare, spring hinges which keep the glasses secure even during the most active recreation and adjustable tips at the temple. The glasses are affordable as well, ranging in cost from $69.99 to $99.99 per pair.